Sustainable Materials A Global Shift Toward Responsible Production

What Are Sustainable Materials

Sustainable materials are resources created or sourced in ways that reduce negative impact on the planet while supporting social equity and economic resilience. These materials favor renewability reuse and recyclability over single use extraction and waste. In practice sustainable materials include naturally regenerative options such as bamboo cork and responsibly sourced timber as well as engineered choices like recycled metals and new biobased polymers. The goal is to close loops in production and consumption so that value is preserved within systems rather than lost to landfill or pollution.

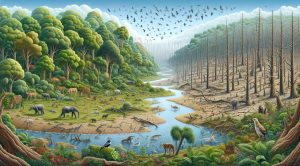

Why Sustainable Materials Matter Now

The urgency to adopt sustainable materials is driven by a convergence of environmental social and financial pressures. Climate change resource scarcity and rising consumer demand for cleaner products push manufacturers to rethink supply chains. Using sustainable materials can lower greenhouse gas output reduce energy use and limit water consumption in production. Beyond environmental gains the shift also responds to market signals. Investors and buyers increasingly reward transparency and resilience which makes sustainable material adoption both an ethical choice and a smart business strategy.

Main Categories of Sustainable Materials

Understanding the main categories helps brands and policy makers choose suitable options for different use cases. Key categories include:

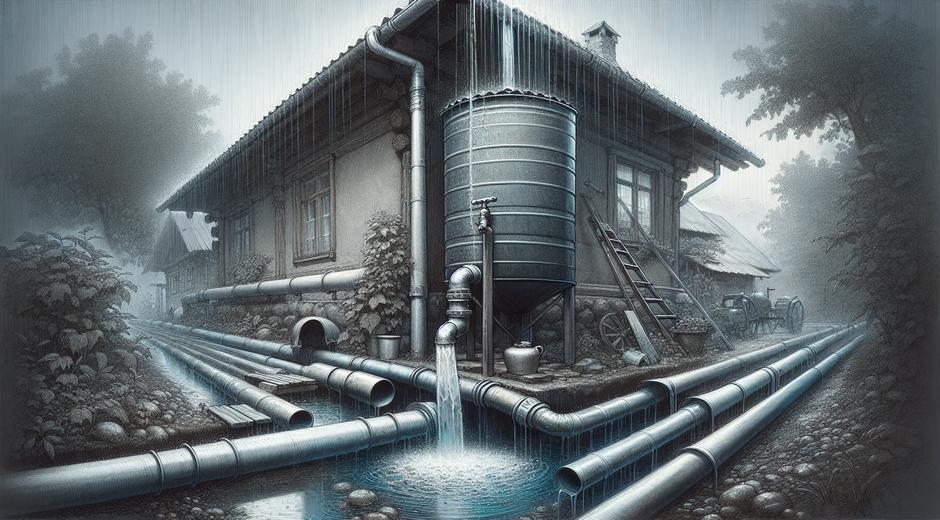

1 Natural rapidly renewable materials such as bamboo cork hemp and natural rubber. These grow back quickly and can be harvested with low impact when managed responsibly.

2 Recycled content materials that use post consumer or post industrial waste such as recycled aluminum glass and plastics. Recycling reduces the need for virgin extraction and can lower life cycle energy use.

3 Biobased materials derived from plants or microbial processes including bioplastics made from starch or cellulose and innovative products grown from mycelium. These can offer degradability under the right conditions and lower fossil fuel reliance.

4 Low impact engineered materials that are designed for long life and reparability. Examples include high quality metals and composites that enable product longevity and eventual recovery of components.

Innovations Driving Material Change

Breakthroughs in material science are expanding the options available to designers manufacturers and consumers. Advances in polymer chemistry allow the creation of biobased polymers that mimic the performance of conventional plastics while using renewable feedstocks. Biotechnology enables production of protein based materials and mycelium structures that can replace foams and packaging. Enhanced mechanical recycling systems combined with chemical recycling unlock the value of mixed waste streams enabling higher quality material recovery. Smart design for disassembly is also rising which ensures that products are easier to refurbish and their materials easier to reclaim at end of life.

Economic Benefits for Businesses

Adopting sustainable materials can reduce exposure to raw material price volatility and regulatory risk. Products that use recycled content or renewable inputs often qualify for green certification which opens access to premium markets and institutional procurement. Operationally companies can realize savings through material efficiency and waste reduction. Moreover sustainability strategies attract talent and improve brand reputation which can translate into stronger market share. For news and insights on how finance and investment are responding to material innovation visit FinanceWorldHub.com to explore case studies and funding trends.

Consumer Demand and Market Signals

Consumers around the world express growing interest in products that safeguard health and environment. Transparent labeling and verified claims about material origin and end of life build trust. Retailers and brands that promote circular offerings such as takeback programs rental models and repair services can deepen customer loyalty. Importantly demand signals extend beyond individual consumers. Large buyers including cities retailers and corporate procurement offices increasingly set requirements for recycled content and supplier sustainability performance which accelerates adoption throughout value chains.

Policy and Standards That Shape Choices

Public policy plays a crucial role in mainstreaming sustainable materials. Regulations on single use waste extended producer responsibility schemes and incentives for recycled content make sustainable options more competitive. Standards for material reporting and third party certification help buyers compare alternatives and avoid greenwash. Harmonized rules across markets support global supply chains by setting clear expectations for material traceability and performance.

Design Principles for Material Efficiency

Design is a decisive lever. Material efficient design reduces mass and volume without sacrificing function. Designers can choose modular components that allow repair and upgrades which extend product life. Selecting materials with clear end of life pathways ensures components can be recycled or composted according to existing infrastructure. Using standardized fasteners and avoiding unnecessary adhesives improves recyclability. By integrating these principles early in development teams can reduce total environmental footprint while simplifying manufacturing and after sales service.

Challenges to Widespread Adoption

Several obstacles remain before sustainable materials become the norm. Supply constraints for certain biobased feedstocks can limit scalability. Performance gaps between novel materials and established options sometimes constrain application in critical sectors. Infrastructure for proper end of life treatment such as industrial composting or advanced recycling is uneven across regions. Finally inconsistent labeling and weak enforcement enable misleading claims. Overcoming these obstacles requires coordinated investment policy support and cross sector collaboration.

How Governments Companies and Communities Can Accelerate Change

A multi actor approach yields the best outcomes. Governments can set ambitious targets provide incentives for research and ensure infrastructure is in place for material recovery. Companies can redesign products adopt science based procurement goals and publish clear data on material flows. Communities and civil society can build local systems for reuse and recycling and hold actors accountable through advocacy and transparent reporting. Collaboration between these groups creates pathways for innovation scaling and equitable access to sustainable materials benefits.

Practical Steps for Businesses and Consumers

For businesses start by conducting a material audit to identify high impact inputs and hotspots across the supply chain. Set targets for recycled content and renewable inputs and invest in product designs that enable longevity and recovery. Engage suppliers early to develop sourcing partnerships and support capacity building in regions that produce key feedstocks. For consumers choose products with clear information about material origin and end of life. Support brands that offer repair options reuse programs and takeback services. Small choices add up and create market demand that shifts production at scale.

Measuring Impact With Life Cycle Thinking

Life cycle assessment offers a robust way to compare materials by accounting for impacts from extraction through production use and disposal. This holistic view reveals trade offs such as higher water use for certain renewable feedstocks or emissions linked to transportation. By using life cycle thinking decision makers can select materials that reduce overall environmental burden rather than shifting impacts between categories. Transparent data and third party verification strengthen the credibility of material claims.

Looking Ahead Opportunities for Growth

The outlook for sustainable materials is strong. Continued research and falling costs will expand applicability across sectors from packaging to construction to electronics. Circular business models and regulatory momentum will create stable demand. Finance mechanisms targeted at circular infrastructure and material innovation will reduce capital barriers for startups and established manufacturers alike. For ongoing coverage of global trends innovation and investment in sustainable material systems you can also follow stories on ecoglobalo.com where we cover market signals and practical insights aimed at change makers.

Conclusion

Sustainable materials are central to a resilient low impact economy. By selecting renewable inputs designing for reuse and investing in recovery infrastructure stakeholders can reduce pollution conserve resources and create new economic opportunity. The shift requires coordinated action across policy industry research and consumer behavior. With smart design transparent data and supportive finance the global transition to sustainable materials can deliver environmental social and economic benefits at scale.